29

2022-03

Detailed Explanation of the Characteristics and Applications of High-Temperature Disc Springs

Author:

Source:

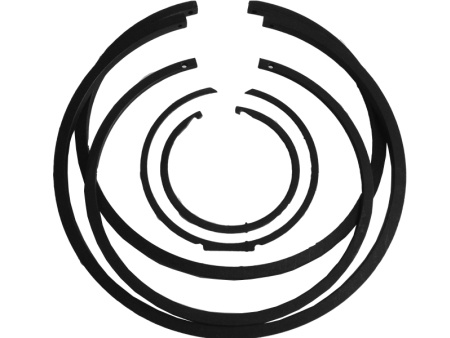

Disc springIt is a conical washer spring made of metal sheets or forged blanks, characterized by small volume, large load, and convenient combination use, with the advantage of centralized load transfer. Different curves can be obtained through single chip, multi-chip, and hybrid combinations, suitable for equipment under high temperature and high pressure or with unstable working pressure and temperature. It plays a buffering role, maintains sealing performance, and protects the stud from fatigue damage caused by overload. It can also serve a locking function, with elastic compensation increasing friction resistance to prevent loosening, keeping the bolts in a good locking working state for a long time.

The disc spring is different from traditional ones. Its main characteristics are large load, short stroke, small required space, convenient combination use, easy maintenance and replacement, and high economic safety. It is suitable for heavy machinery with limited space and heavy loads. The optimal use range of its compression stroke is between 10% to 75% of its maximum compression stroke.

Characteristics of high-temperature disc springs

a. The preload of high-temperature disc springs changes repeatedly due to thermal expansion and contraction, with strong compensation functionality, maintaining constant preload to prevent bolt fatigue and gasket failure.

B. Changes in medium pressure lead to changes in preload, and high-temperature disc springs can compensate for the changes in preload caused by medium variations, preventing bolt and gasket failure.

C. Mechanical vibrations cause changes in preload, and high-temperature disc springs can effectively absorb mechanical vibrations, avoiding bolt loosening caused by mechanical vibrations, ensuring long-lasting and reliable sealing.

Application equipment for high-temperature disc springs

Steel pipe columns; bearing preload, roller bearing seats, core shafts; flywheel drive overload protection: mechanical starters; conveying devices; impact power stations; brakes, high-pressure safety valves, rectifying components; boilers, calcium carbide furnaces. Currently widely used in industries such as metallurgy, engineering, electricity, machine tools, and construction. For example: molds, supports, clutches, brakes, bridge buffers (shock absorbers), bearing preload, safety overload, heavy machinery, mechanical starters, control, valves, industrial electric furnaces, indexing, clamping, and other devices.

Correctly selecting disc springs is crucial for controlling leakage. It can only play a practical role when it operates in a constant load area. If the pressure is incorrectly selected to be too low, after a 30% relaxation of the bolt preload, it cannot provide the required sealing. The effect is like not using it at all. If the pressure is incorrectly selected to be too high, it will lead to deformation, exceeding the elastic limit of the gasket material, resulting in worse effects than not using it.

Compared with other types of springs,Disc springthe unit volume deformation energy is greater, providing better buffering and shock absorption capabilities. Especially with the use of stacked combinations, due to the damping effect of surface friction, the absorption of impacts and dissipation of energy are more significant.

Disc spring

Latest Blog

2021-02-25

Chongqing Jinggu Industrial and Trade Co., Ltd. official website has been launched.

Chongqing Jinggu Industrial and Trade Co., Ltd. official website has been launched.

2021-02-25

The China International Motorcycle Parts Exhibition is held in Guangzhou.

On November 16, the Central Broadcasting Network reported from Guangzhou (Reporter Zheng Shu)

2021-02-25

The China Export Motorcycle Quality Technology Promotion Committee was established in Chongqing.

On March 31, at 14:30, Hu Long Net reported (Chief Reporter Huang Jun) that recently

2021-02-25

An Italian company releases a custom electric motorcycle with 3D printed parts.

According to foreign media reports on March 29, the Italian motorcycle manufacturer recently

2021-07-07

What is a cover plate

Cover pressure plateis a new type of bonding material,is also a commonly used plastic material